Figure 213 Crowning of Pulleys. Face Width The length of a pulleys cylindrical bodyThis area is intended to act as the contact surface for the conveyor belt.

How Crowned Pulleys Keep A Flat Belt Tracking

The usual figure for the amount of crowning is 18 inch per foot of pulley width.

. Ad We Provide You With The Tools To Tackle Tough Challenges. The amount of curvature required in actual machinery is small. A lot of it depends upon the belt material and belt width to pulley width ratio.

Get the Deals now. 5 CONVEYOR PULLEY SELECTION GUIDE PulleyCore Diameter The outside diameter of the cylindrical body of a conveyor pulley without coating. Overall i would say the belt manufacturer sets the standards for the crowns if needed.

Flat belt variable cast iron. There is no point in over crowning a pulley as too high a crown will possibly stretch the belt in the middle and reduce the effectiveness of the overall contact. The pulleys may be made of cast iron cast.

It is ideal fora lot of work - especially flat work as there is little or no crown on that front pulley. Dimensions for V-Guides and Grooves. 45 out of 5 stars 2.

What our customers are saying. To crown or not to crown a lagged pulley. One of the woven flat belts I had ordered needed a specified crown of 15 to 3 on both pulleys based upon diameter.

Compare this product Remove from comparison tool. The driven front roller has very little or no crown. You may be right about the strip pair concept but crowning can also be explained without assuming a tension change in the strip pairs you suggest but the fact that as the belt tends to move axially say to the right the angular contact on the left strips increases and the right strips angle decreases so the axial force component on the left increases at the same.

Get it Tue Mar 15 - Thu Mar 17. Made with built- in free-spinning ball bearings theyre installed on shafts or belt tensioners to remove slack from timing belts. Ad Best Deals On thousands of products.

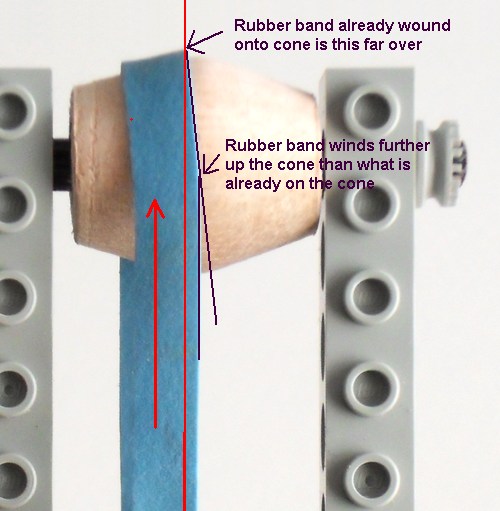

Price and other details may vary based on product size and color. In case of flat belts thickness of the rim is increased from the centre so that it gets convex shape as shown in figure 213. Order to allow the belt to travel in a line normal to the pulley faces.

Ad Millions of Items on One Easy-to-Use Site with Outstanding Customer Service. Used alone these covers optimize belt performance. Flat Idler Pulley 325 Flat Diameter 38 Bore Steel.

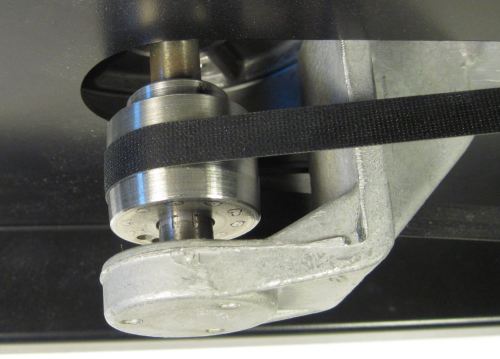

A friction cover or rubber lagging helps to increase the traction between the conveyor belt and the drive pulley. Thus the difference in maximum and minimum radii of a crowned 6-inch wide pulley would be 116 inch. Order today with free shipping.

High-Strength HTD Timing Belt Idler Pulleys Keep high torque drive HTD timing belt systems running tightly with these idler pulleys. The pulleys are used to transmit power from one shaft to another by means of flat belts V-belts or ropes. We Are Committed to Making Your Job Easier - Shop our Endless Aisle.

Translating this to a 6 inch wide pulley means that the diameter at the peak of the crown should be 0625 inch for a 4 inch wide pulley 042 inch. Crowning Data for Flat Belt Drives. This is known as crowning of the pulley.

05-13-2011 0641 PM 4. Flat and grooved types for variable speed belts Grooved sheaves machined to match belt width and angle of standard belts Made of durable cast iron to assure best possible. The pulleys must be in perfect alignment in.

When a flat belt runs over two pulleys only one of them needs to be crowned to achieve lateral stability. Should be carefully selected in order to have a desired velocity ratio. To prevent the flat belt from slipping at least one pulley must be crowned preferably a larger pulley or a pulley with the greatest contact angle.

The greater the contact angle the better the following effect of the belt. 1-24 of 189 results for Mechanical Flat Belt Pulleys RESULTS. Fill Your Cart With Color today.

It is a spring-loaded rubber with spiral grooves that take up when the belt is tightened and when the work is sanded on the front of the belt. It helps in preventing the belt from running off the pulley by bringing it to the mid-plane of pulley whenever it moves to sides. Pulley crowning is an essential design element for tracking control of flat conveyor and power transmission belts.

In practice based on the total length of the drum the typical design of a crown pulley is applied. Crowning Data for Conveyor Belt Rollers. Usually the available pulleys are crowned to ISO 22.

Ad Check Out Flat Face Pulley on ebay. Finish Diameter The outside diameter of a coated pulley core diameter 2 times the coatingwrap thickness.

How Crowned Pulleys Keep A Flat Belt Tracking

Crowning Data For Conveyor Belt Rollers Splawn Belting

Crowned Pulleys Which Option Is Right For You Sparks Belting

To Crown Or Not To Crown A Lagged Pulley Habasit Expert Blog

Drum Pulley Lagging All State Conveyors Innovative Solutions Provider

Pulleys For Flat Belts Flanged Crowned Press Fit Urethane 6 To 32mm Width Misumi Misumi Misumi

0 comments

Post a Comment